3D Services

The modern industrial landscape is undergoing a transformative evolution driven by advanced 3D technologies. The use of simulations, digital twins, as well as virtual and augmented reality is revolutionizing not only production processes, but also the way companies plan, develop and interact. These technologies enable more precise visualization and analysis, foster innovative solutions and provide enhanced capabilities for error detection and process optimization. Together, these 3D services form a robust technological foundation that enables companies to effectively meet the challenges of Industry 4.0 and secure a competitive edge in an increasingly digital world.

Simulations and real-time simulations

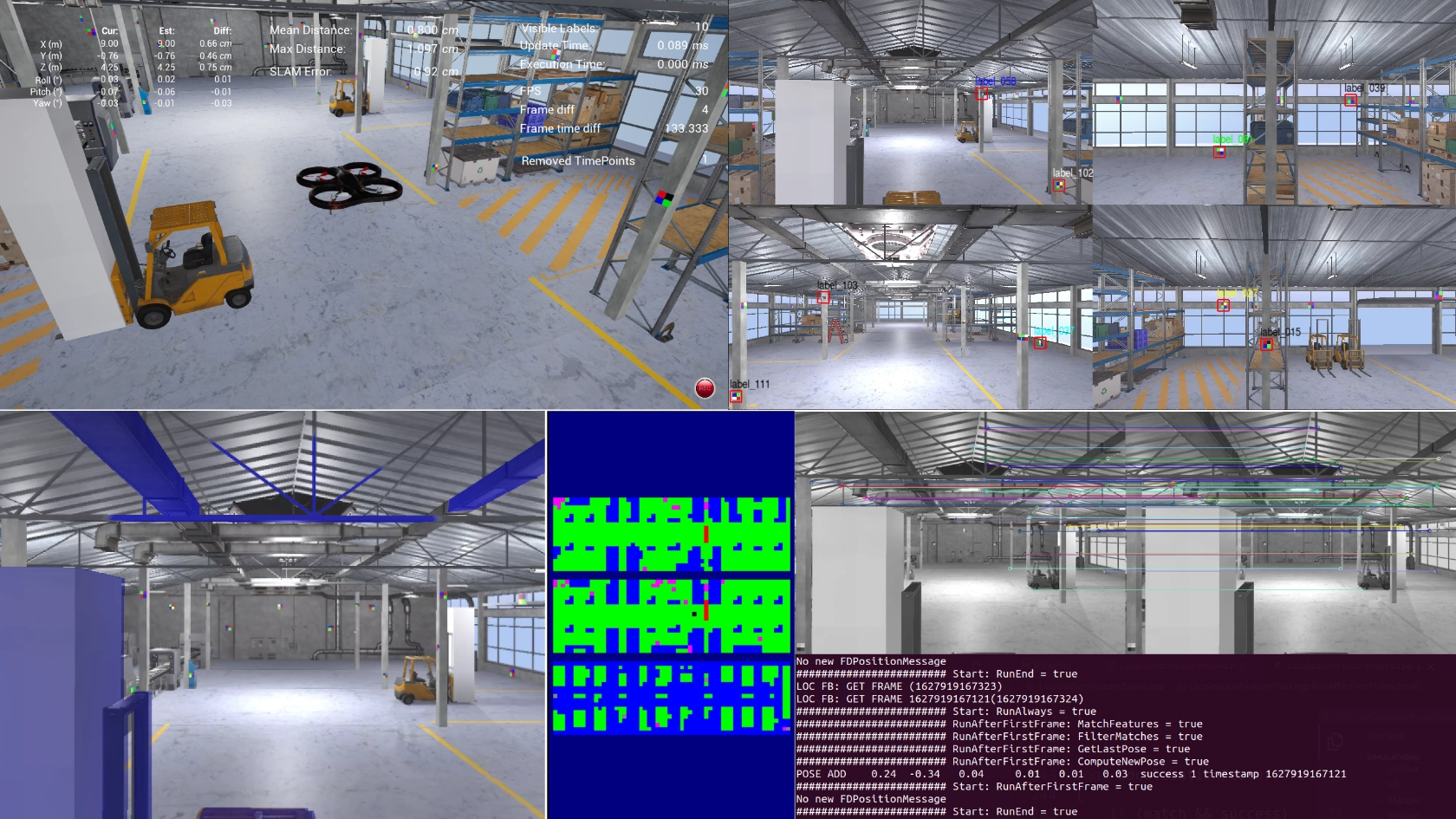

Simulation technologies are critical in modern industry because they make it possible to model and analyze complex processes before physical prototypes are built or changes are made in production. They are especially powerful in 3D real-time simulation, where they provide realistic and interactive environments in which different scenarios can be tested safely and cost-effectively.

To make simulation a truly powerful tool, it is necessary to create a highly detailed, realistic, real-time capable, dynamic and flexibly adaptable 3D environment. This is achieved by integrating the created digital twins into a powerful 3D development environment. It is also necessary to simulate both the dynamic behavior of the industrial environment and the behavior of the autonomous system. A key part of such a simulation consists of virtual sensors that act as digital counterparts of real sensors, capturing information from the simulation environment and providing it for the implementation of autonomous control. Higher-level perception and intelligent autonomous control functions are implemented using DNNs. On the basis of such simulation systems, we can investigate a wide variety of scenarios – something that would not be feasible in the real world due to effort, time or safety constraints.

Use cases

Autonomous systems: For drones and other autonomous systems, real-time simulations make it possible to test navigation algorithms and operating strategies in a controlled virtual environment. This is essential to ensure that these systems operate efficiently and safely under real-world conditions.

Photovoltaic systems: Simulation software can be used to model the performance of PV systems under different climatic and geographic conditions. This helps determine optimal configurations for maximum energy efficiency.

Inspection of overhead lines and factory halls: By using simulations, maintenance strategies can be developed that minimize risk and increase safety. Virtual models of plants and infrastructure enable maintenance work to be planned and executed with precision.

Technology and tools

Modern 3D real-time simulations leverage advanced rendering technologies and physics-based models to create highly realistic conditions. Tools such as Unreal Engine 5 allow us to build detailed and highly interactive 3D environments that are not only visually impressive but also deliver physically accurate simulations.

Benefits of our simulations and real-time simulations

- Cost efficiency: Reduces the need for physical prototypes and enables companies to detect and correct design and functional issues at an early stage.

- Risk minimization: Provides a safe platform for testing and optimizing systems under extreme or hazardous conditions without assuming real-world risk.

- Innovation driver: Enables rapid iteration and experimentation with design concepts, leading to more innovative and creative solutions.

By combining these technologies and methods, companies strengthen their ability to respond quickly to market changes and continuously improve their systems while ensuring safety and compliance.

Digital twins and virtual environments

Digital twins are virtual representations of physical objects or systems. They use real-time data to create a dynamic model that simulates the behavior, condition and lifecycle of a physical counterpart in a virtual environment. This technology is invaluable for optimizing production processes, maintaining assets and developing new products.

Creating digital twins of real-world objects and complex environments is a key prerequisite for automation projects that aim at building or reconfiguring entire production environments. Even though highly capable tools and digital data sources are available today, it remains challenging to generate high-quality, compatible and real-time-capable 3D data from them. To achieve this, 3D data from different sources – using various 3D tools (CAD systems, 3D content creation tools and development systems for real-time 3D simulations) – is transformed into a unified data format. In addition, we ensure that unnecessary details are removed from 3D models to reduce complexity and thus guarantee real-time capability.

Use cases

Smart factory: In the smart factory, digital twins enable detailed monitoring and control of manufacturing processes. They provide insights into machine performance, preventive maintenance and potential system failures before they occur.

Smart city: Digital twins of cities or urban infrastructures support urban planning, traffic flow analysis and energy management. They allow different scenarios to be tested and the impact of changes to be understood before implementation.

Product development: By simulating products in virtual environments, companies can shorten development times and accelerate time-to-market. Digital twins make it possible to test products under various conditions and feed the findings directly back into the design process.

Technology and tools

Virtual environments: Comprehensive virtual platforms are required to manage the complex data volumes generated by digital twins. These platforms enable the integration and analysis of data from various sources in order to create a coherent model.

Unreal Engine 5: Used to build realistic and interactive 3D environments for digital twins. Its high visual fidelity and ability to process large data volumes make it ideal for representing complex digital twins.

Benefits of our digital twins and virtual environments

- Optimized decision making: Real-time data and simulations improve decision-making processes at all levels of an organization.

- Cost reduction and efficiency gains: Errors are identified before physical implementation, leading to significant savings in operating costs.

- Increased asset availability: Preventive maintenance and fast fault resolution based on insights from digital twins increase availability and reliability.

Digital twins and virtual environments form the foundation of a new era of industrial digitalization, in which simulations and real-time data are used to optimize processes and drive innovation. They enable companies to respond faster to change and design their systems efficiently and sustainably.

Virtual and augmented reality technologies

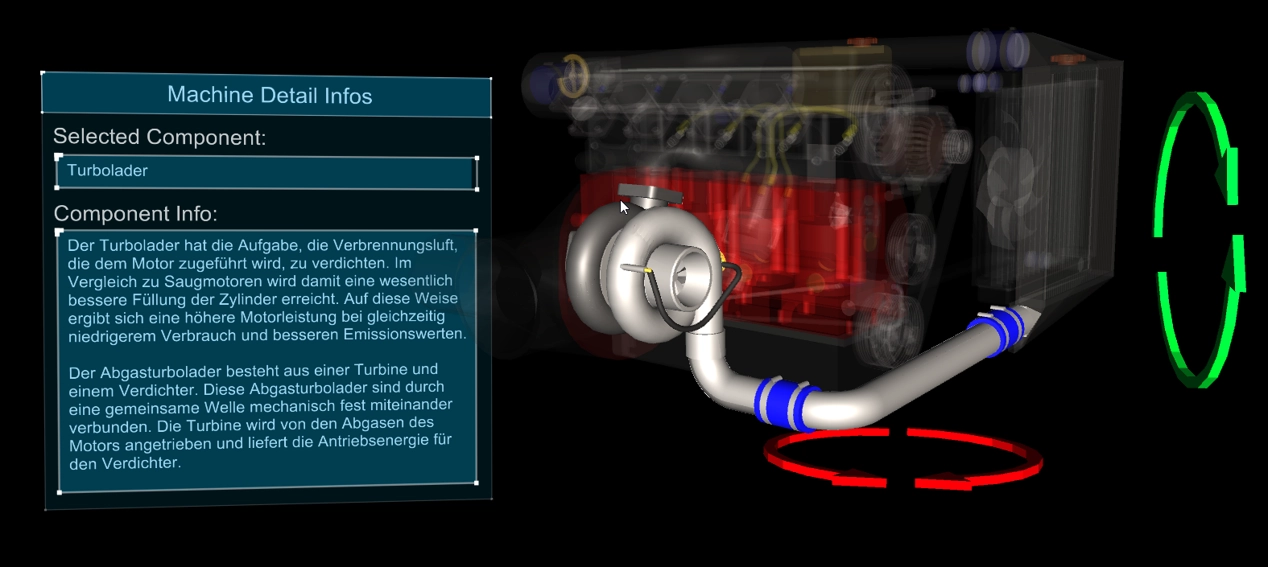

Virtual reality (VR) and augmented reality (AR) are key technologies that are fundamentally changing how companies design, train and interact. These technologies extend human perception and interaction with digital information and create immersive and augmented experiences that can be applied directly in real-world environments.

Use cases

Training and simulation: VR is frequently used for training in environments that would be too dangerous or too expensive to replicate in the real world. AR provides real-time overlay information, which is particularly useful for repair and maintenance of complex machinery.

Design and visualization: Engineers and designers use VR to design and test new products in a fully simulated 3D environment. AR makes it possible to visualize design changes directly on a physical prototype, speeding up and improving development.

Remote maintenance and support: AR glasses enable technicians on site to communicate with experts in real time. Experts see what the technician sees and can overlay instructions directly into their field of view.

Technology and tools

Unreal Engine 5: One of the most advanced development platforms for creating highly realistic VR and AR experiences. Its ability to generate dynamic lighting and photorealistic graphics makes it ideal for immersive training and simulation solutions.

XR headsets: Devices such as VR headsets and AR glasses are essential for delivering immersive and augmented experiences. They have evolved rapidly to become more comfortable and powerful, offering users interactive experiences with high resolution and low latency.

Benefits of our VR and AR technology

- Increased safety: VR and AR enable training in safe conditions, significantly reducing the risk of accidents during training.

- Improved efficiency: Faster design iterations and enhanced capabilities for maintenance and repair through direct, intuitive visual guidance.

- Cost reduction: Reduces travel costs and downtime through remote support and virtual meetings.

Overall, VR and AR offer transformative opportunities for industry to increase efficiency, lower costs and improve employee engagement and satisfaction. They have become an indispensable part of modern industrial strategies.