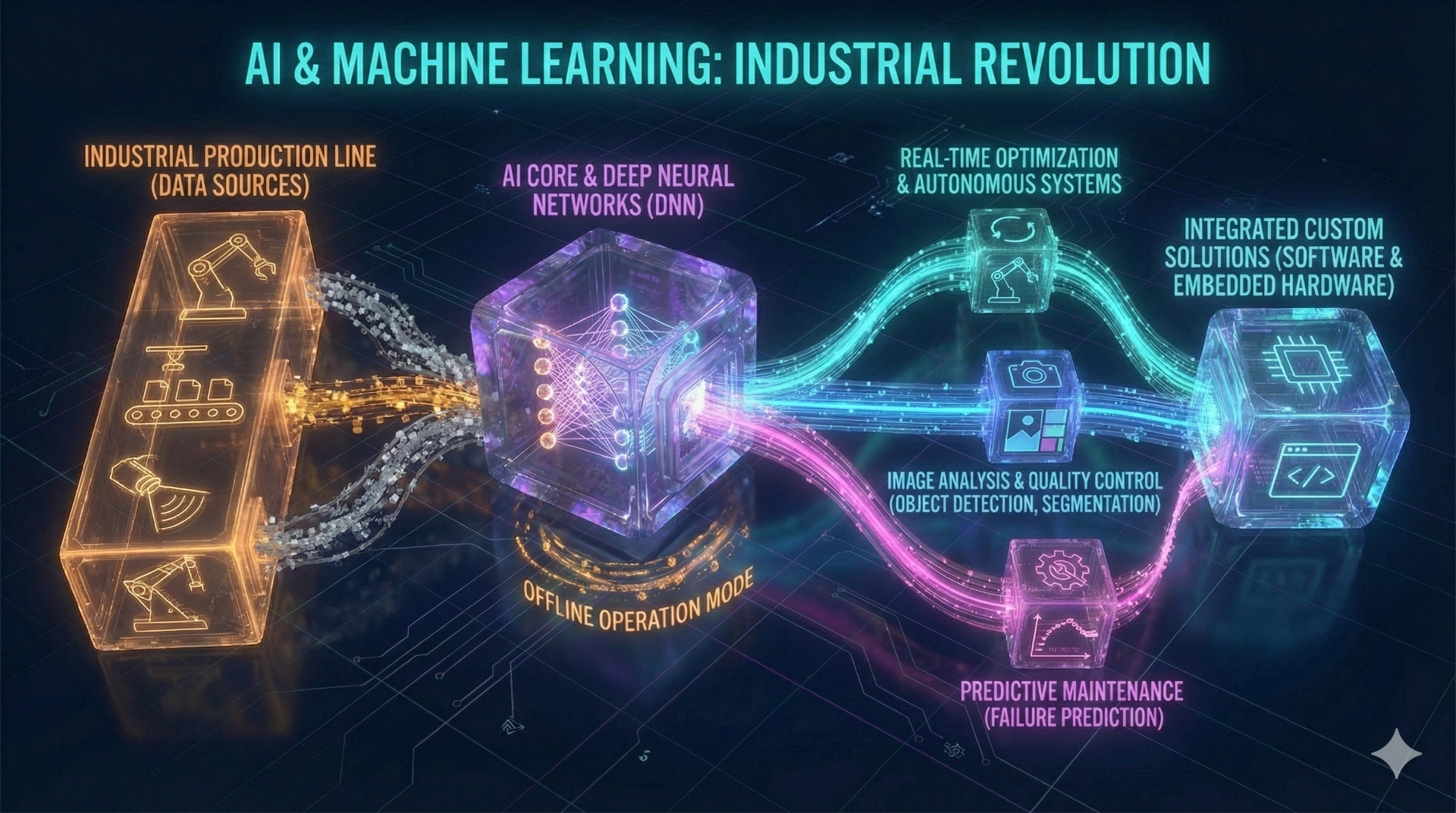

AI and Machine Learning

The integration of artificial intelligence (AI) and machine learning is transforming industrial manufacturing and production. These technologies offer unprecedented opportunities to increase efficiency and productivity by automating processes and enabling real-time optimization. From precise surface inspection and treatment using specialized cameras to the development of autonomous systems and robotics based on embedded AI hardware – our applications are diverse and deeply integrated.

By using deep neural networks (DNN), new dimensions of data analysis and processing become possible. Whether in object detection, image and video segmentation, or in quality monitoring and process optimization – our AI systems learn from large volumes of operational data and continuously improve their decision-making. This leads to a significant reduction in downtime and an increase in overall equipment effectiveness (OEE).

The predictive capabilities of machine learning are also transforming the maintenance of machines and systems. Predictive maintenance uses algorithms to anticipate future failures and recommend preventive actions before costly breakdowns occur. Combined with our advanced analytics tools, this enables forward-looking and demand-driven maintenance.

In this context, not only the technological capabilities themselves are crucial, but also the integration and implementation into existing systems. The development of application-specific software, the optimal use of embedded AI hardware, and the ongoing adaptation and refinement of algorithms are all key to successful practical use. To ensure a well-orchestrated solution, we deliver everything tailored from a single source.

Predictive maintenance

Predictive maintenance is a central component of modern production facilities. By applying AI and machine learning, maintenance needs are predicted before actual failures occur. Sensors continuously collect data on machine operating states, which is then analyzed to identify patterns and anomalies. This enables maintenance and part replacement at the right time, extending asset lifetime and reducing costs caused by unplanned downtime.

Predictive analytics

Predictive analytics uses machine learning and advanced data analysis techniques to forecast future events based on historical data. In industrial environments, this approach makes it possible to detect potential failures and maintenance needs at an early stage. By analyzing data patterns from machine operations and production processes, risks can be minimized and efficiency increased. Predictive analytics helps reduce unplanned stoppages and improve productivity through optimized maintenance schedules and resource allocation.

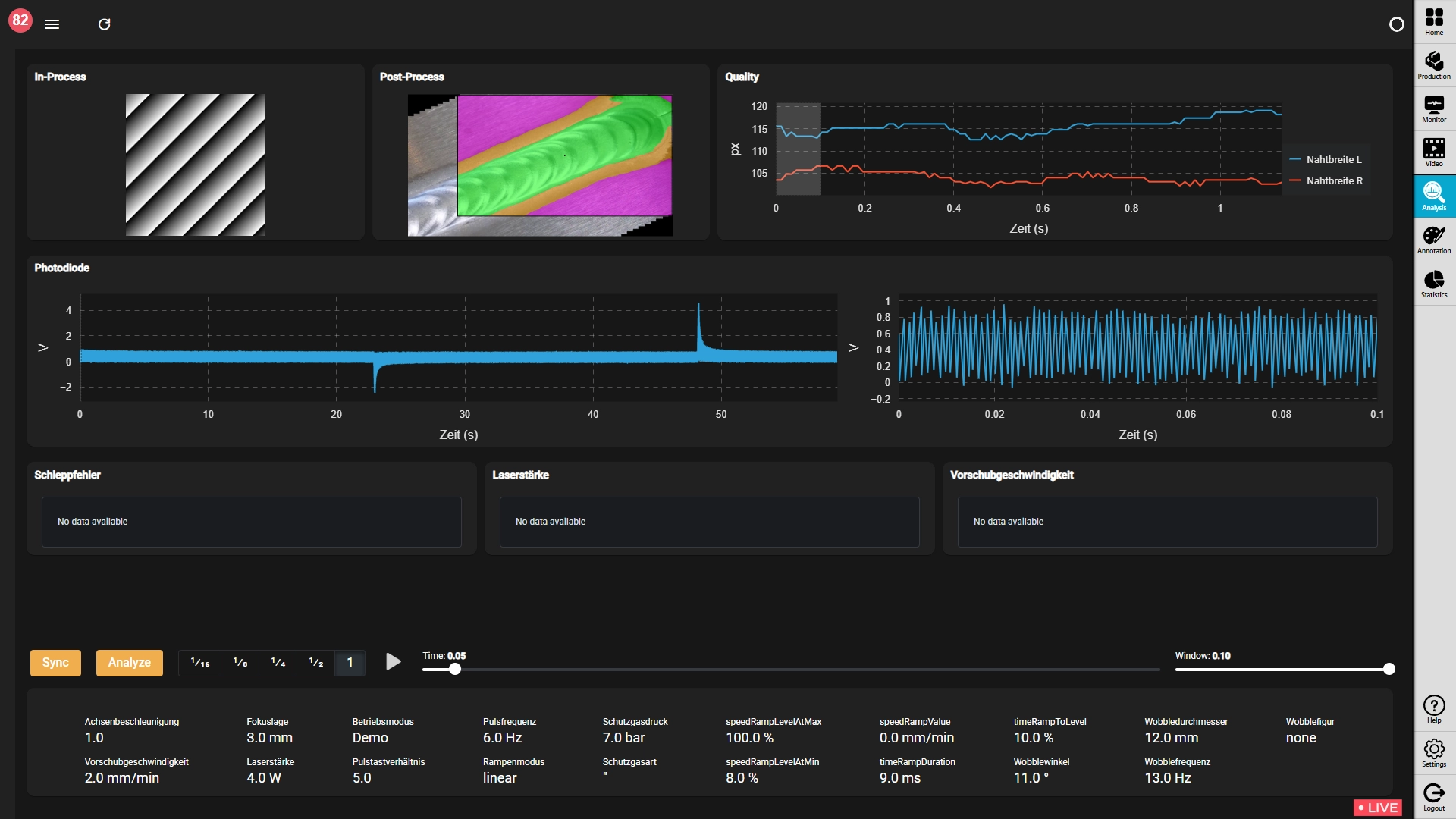

Surface quality assurance with specialized cameras

Advanced surface quality assurance using specialized cameras enables precise acquisition and analysis of surface characteristics in real time. This technology uses high-resolution cameras and machine learning algorithms to detect irregularities, wear or defects. Integrating these systems leads to improved quality control, reduced maintenance costs and higher production efficiency. Continuous monitoring and analysis of surfaces helps safeguard the integrity of production processes and extend the lifetime of treated materials.

DNN applications in industrial automation

By using deep neural networks (DNN), extensive perception functions and the implementation of flexible, intelligent behavior for complex tasks become possible. Depending on the specific use case, different DNN architectures may be required. Selecting the appropriate DNN and implementing it correctly therefore represent key tasks.

In addition, designing a suitable training concept and creating high-quality training data are essential prerequisites for building a deployable deep neural network. To keep the effort for generating training data manageable, powerful AI methods and tools are used, such as labeling tools for manual, semi-automatic and fully automatic annotation, as well as augmentation techniques that automatically generate additional training data. Conducting DNN training, performing subsequent tests, and iteratively adapting and extending the test data continue until the desired DNN quality is achieved.

Beyond their use in autonomous systems, deep neural networks are also applied in other automation scenarios – for example in intelligent handling and sorting processes or in intelligent control systems for manufacturing process optimization.

Object detection

Deep neural networks are particularly effective for object detection in complex production environments. They identify and classify objects in real time, which is essential for automated sorting, quality checks and robot-based systems. Our technology enables machines to make autonomous decisions based on visual data, increasing both efficiency and accuracy in production.

Image and video segmentation

DNNs are also used for image and video segmentation. These processes divide digital images and videos into multiple segments (or objects), enabling detailed analysis and processing. In industrial applications, this technique helps detect specific features in materials or components that are needed for precise quality inspections and subsequent automated processing steps.

Quality monitoring

In quality monitoring, DNNs leverage their ability to detect complex patterns and irregularities. Our systems monitor product quality in real time and trigger alerts in case of deviations, enabling rapid responses and corrections. Continuous monitoring and analysis of production data are key to maintaining consistently high quality standards.

Process optimization

DNNs play a crucial role in process optimization by continuously analyzing data and deriving optimization suggestions. Our networks learn from production workflows and automatically adapt to achieve efficiency gains and reduce material usage as well as cycle times. Their adaptability makes them an important tool for continuous improvement of industrial processes.

Software development for NVIDIA embedded AI hardware (autonomous systems and robotics)

Developing software for embedded AI hardware, particularly for NVIDIA platforms, is a key element in realizing autonomous systems and robotics. NVIDIA’s powerful GPUs and specialized SDKs such as JetPack provide the computing power and tools required to efficiently execute complex algorithms for machine learning and deep neural networks. These technologies make it possible to build autonomous systems that can learn, navigate and interact in real time.

Typical applications include autonomous vehicles, intelligent industrial robots and drones that can precisely perceive and respond to their environment. Software development for these platforms requires deep expertise in AI, machine learning and robotics in order to fully leverage the capabilities of the hardware and create innovative solutions for industrial use cases.