Process Optimization

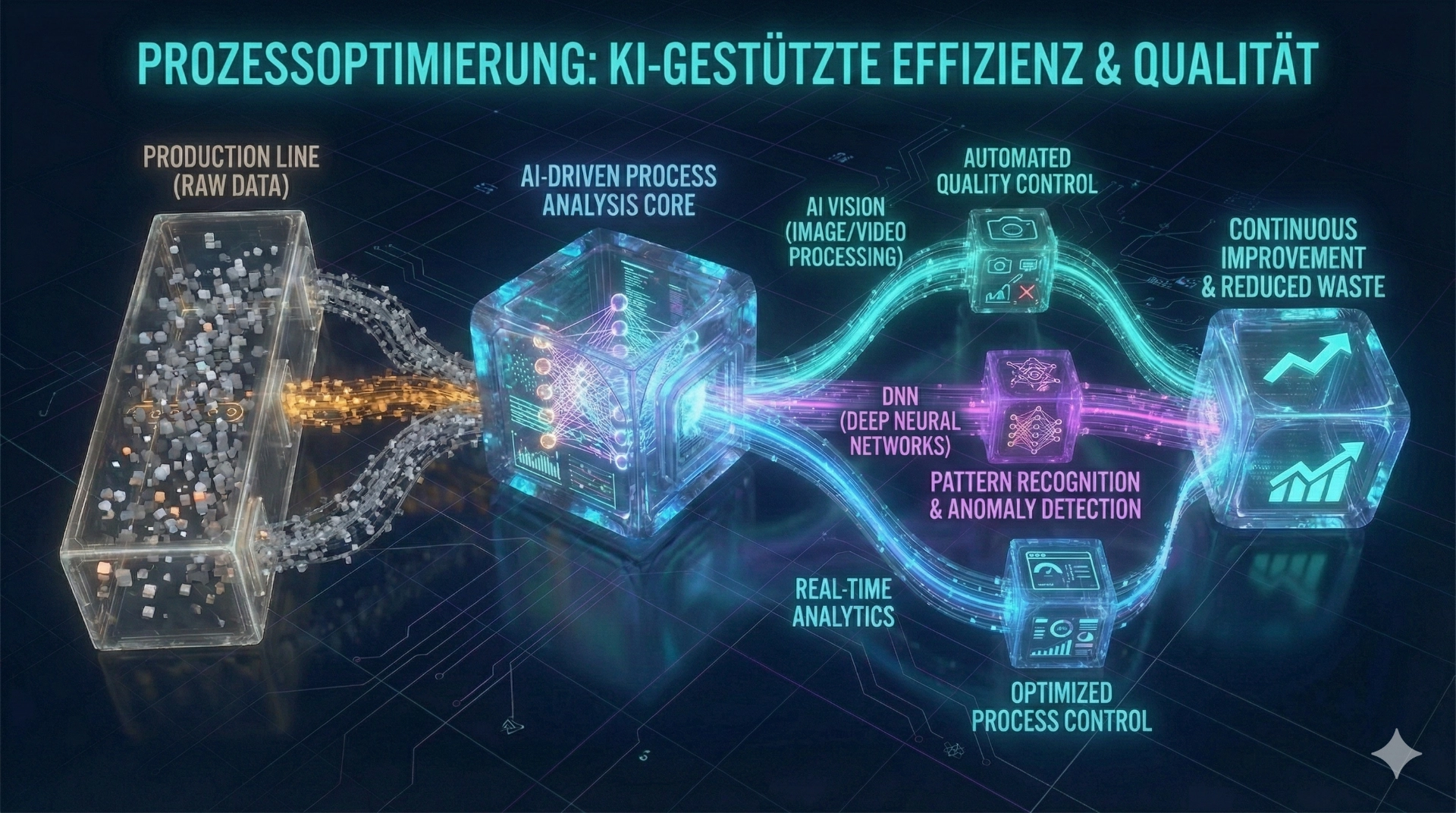

In today’s industrial landscape, process optimization plays a central role in increasing efficiency and quality. By using our AI and machine-learning solutions, new ways are opening up not only to monitor production processes, but also to actively improve them. These technologies enable in-depth analysis and automation that go far beyond the possibilities of traditional methods.

Process analysis: the key to quality assurance

Process analysis is the starting point for every form of optimization we provide. It delivers the data needed to identify patterns and uncover potential improvements. Combined with AI, this process becomes not only faster and more efficient, but also more precise. AI systems can process vast amounts of data in real time and derive actionable insights that flow directly into process control.

By analyzing production data in detail, weaknesses and inefficiencies can be identified with high precision. This data-driven approach helps companies make well-founded decisions to improve production quality. It forms the foundation on which our subsequent optimization measures are built.

Implementing quality detection using deep neural networks (DNN)

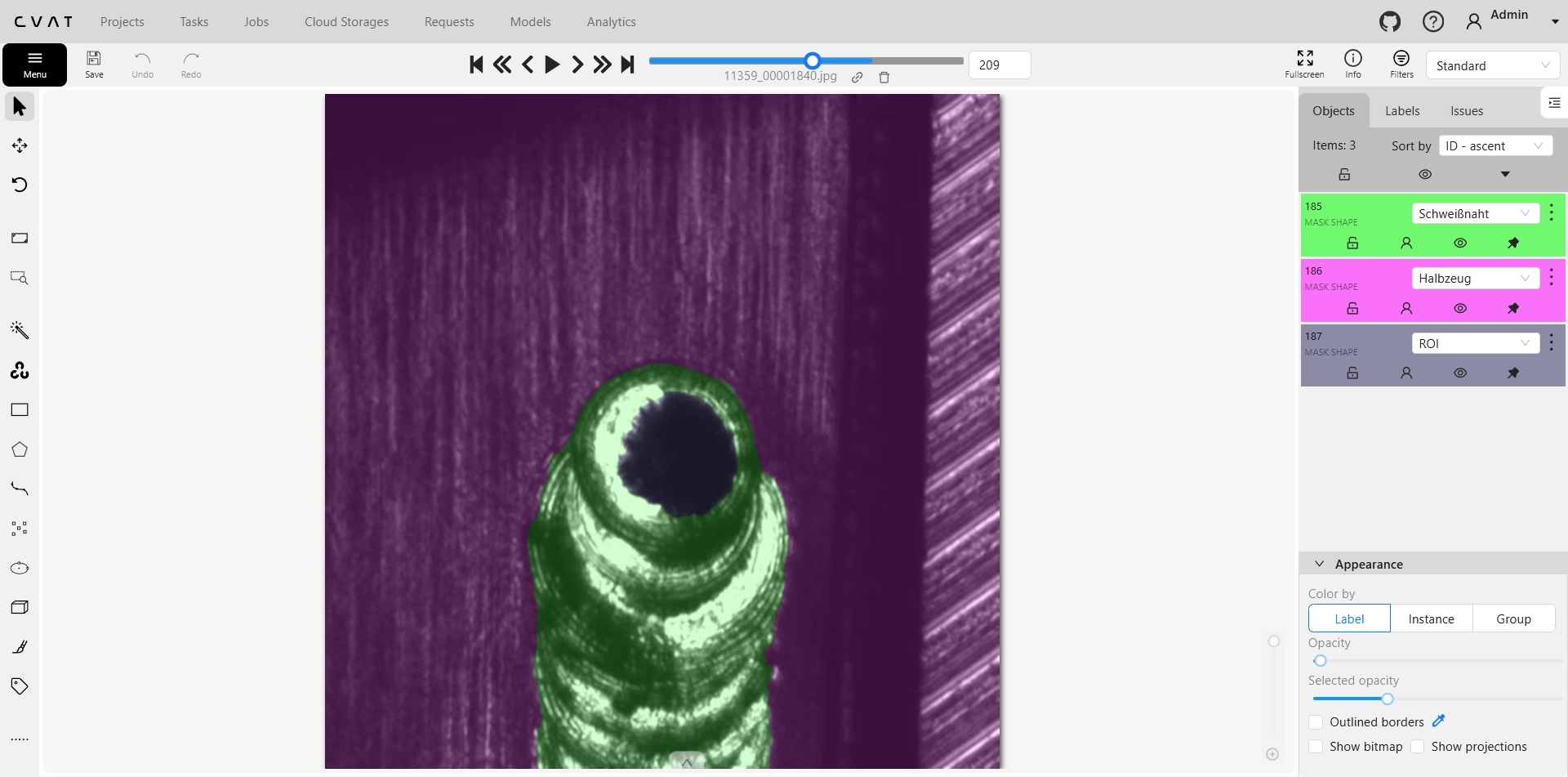

Deep neural networks (DNN) enable unprecedented accuracy in automated quality inspection. They are capable of detecting complex patterns and anomalies in production data that remain invisible to traditional methods. This leads to a significant reduction in scrap and an optimization of manufacturing processes. DNNs are tailored to the specific requirements of the manufacturing environment and can learn independently from completed inspections.

Process optimization in complex production processes

Particular challenges arise when optimizing complex production processes, especially in small- and medium-batch manufacturing. Here, data-driven methods make it possible to design even highly complex workflows efficiently. By continuously capturing and analyzing process data, production sequences can be dynamically adjusted and optimized, resulting in a significant increase in overall efficiency.

Parametric optimization for increased efficiency

Parametric optimization plays a central role in fine-tuning production processes. By analyzing and adjusting process parameters, companies can reduce operating costs while improving product quality and throughput times. This method is based on the systematic collection and evaluation of relevant data to determine the optimal settings for each step in the production process.

AI-based image and video processing

The integration of AI-based image and video processing technologies marks a revolutionary step forward. With advanced algorithms, industrial camera systems can now analyze visual data in real time. These systems detect and classify defects with a level of precision that surpasses human inspectors. The AI continuously learns and improves its results, leading to steadily increasing detection rates and reliability.

From theory to practice: implementation in industry

Practical applications of AI in process optimization range from automated quality assurance using image and video analysis to complex process control based on digital twins and parametric optimization. These technologies enable companies to continuously refine their production processes and adapt them to changing requirements.

The combination of process analysis and AI-driven optimization forms the backbone of our modern quality assurance and process optimization solutions. These approaches are crucial for companies that want to remain competitive in a fast-moving world. By working closely with us as a technology partner, companies can master the challenges of modern manufacturing technologies and achieve sustainable improvements across their production lines.