Surface Monitoring

Surface monitoring is a practical use case of our AI-supported process optimisation and quality assurance. It combines automated quality evaluation with data-driven optimisation of complex manufacturing processes – directly integrated into ongoing production.

Surface monitoring as a use case of process optimisation and quality assurance

In complex manufacturing processes such as laser welding, quality and process stability are closely linked. Even small deviations in parameters, material or geometry can have immediate effects on the result. With our surface monitoring solution, we help you to automatically evaluate quality, improve processes in a targeted way and document results in a product-specific and traceable manner. Our surface monitoring solution addresses exactly this:

It is not an isolated visual inspection, but part of a continuous, process-oriented system that:

- automatically detects quality features,

- evaluates process data in a contextualised way, and

- systematically derives optimisation potential.

Surface evaluation serves as a central source of information for targeted process improvement and reproducible process control.

Integrated quality control & quality passport

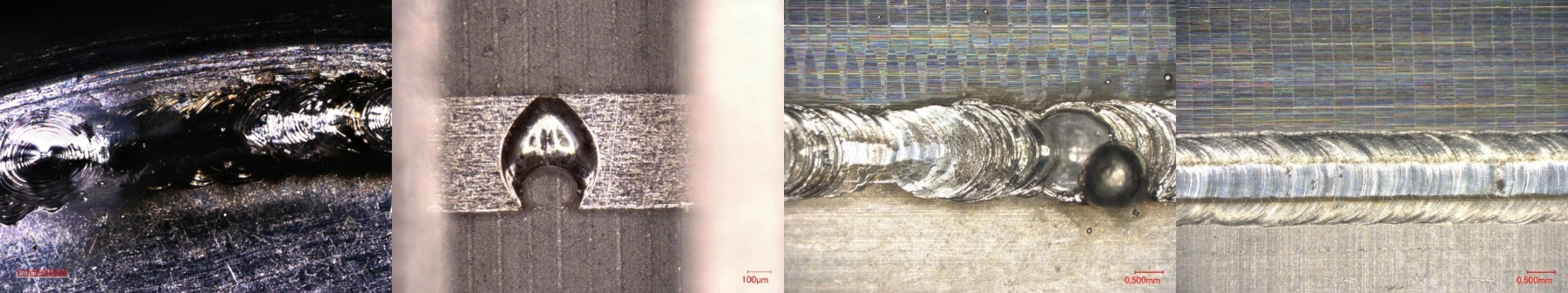

Our solution includes automated, product-specific quality control that is directly integrated into the manufacturing process. Visible surface characteristics such as seam geometry, regularity or typical defect patterns (e.g. spatter, pores, cracks) are systematically captured and evaluated. On this basis, a product-related quality passport can be generated for each manufactured part – traceable, objective and data-based.

The foundation: process-near data acquisition

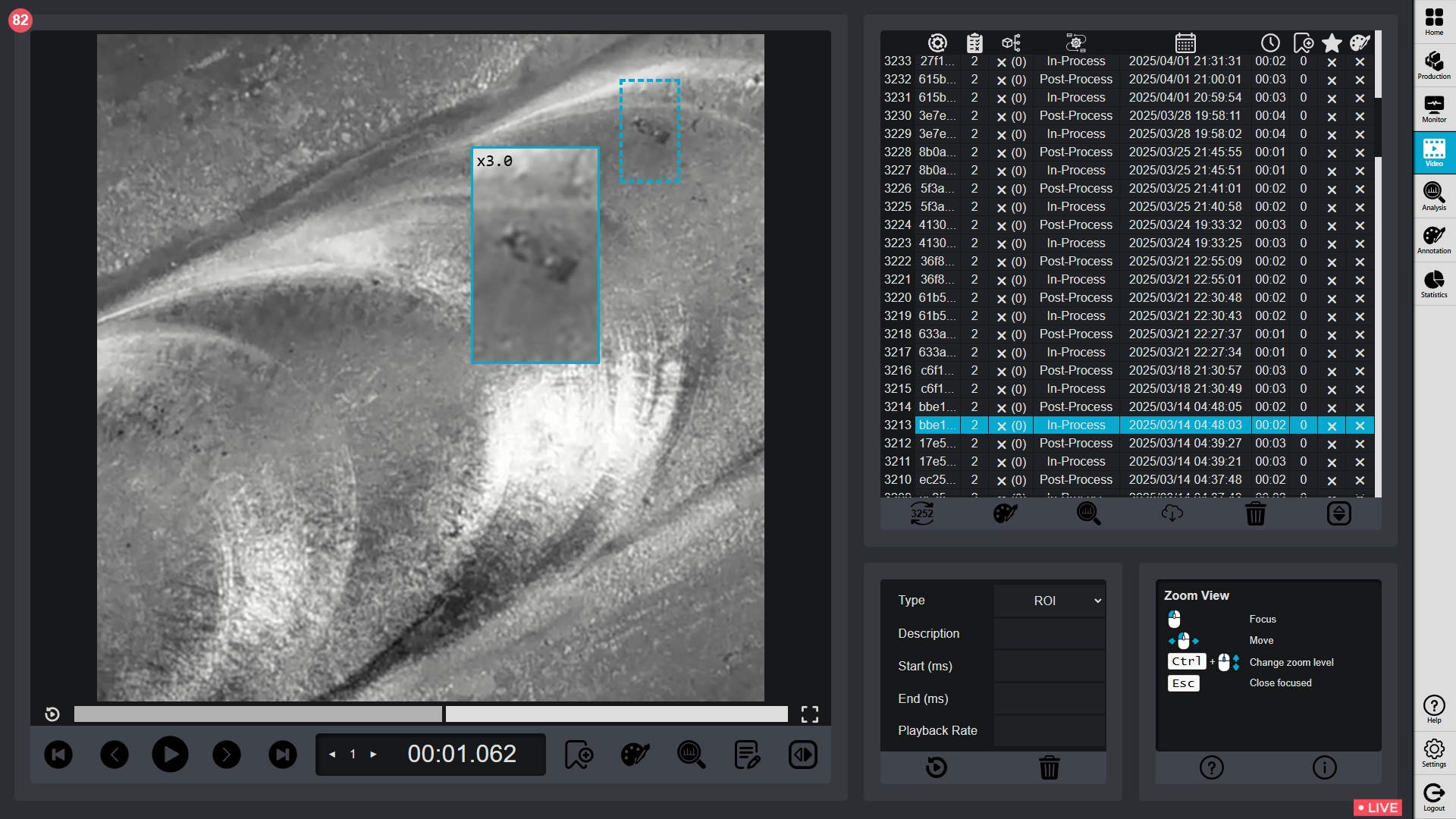

A central element is process-synchronous acquisition of image, video, sensor and machine data:

- high-resolution cameras capture the process at high frame rates

- machine process signals are synchronised and integrated

- sensor and time series data complement the visual evaluation

Data acquisition is fully embedded into the production flow and enables seamless assignment of process, workpiece and quality evaluation.

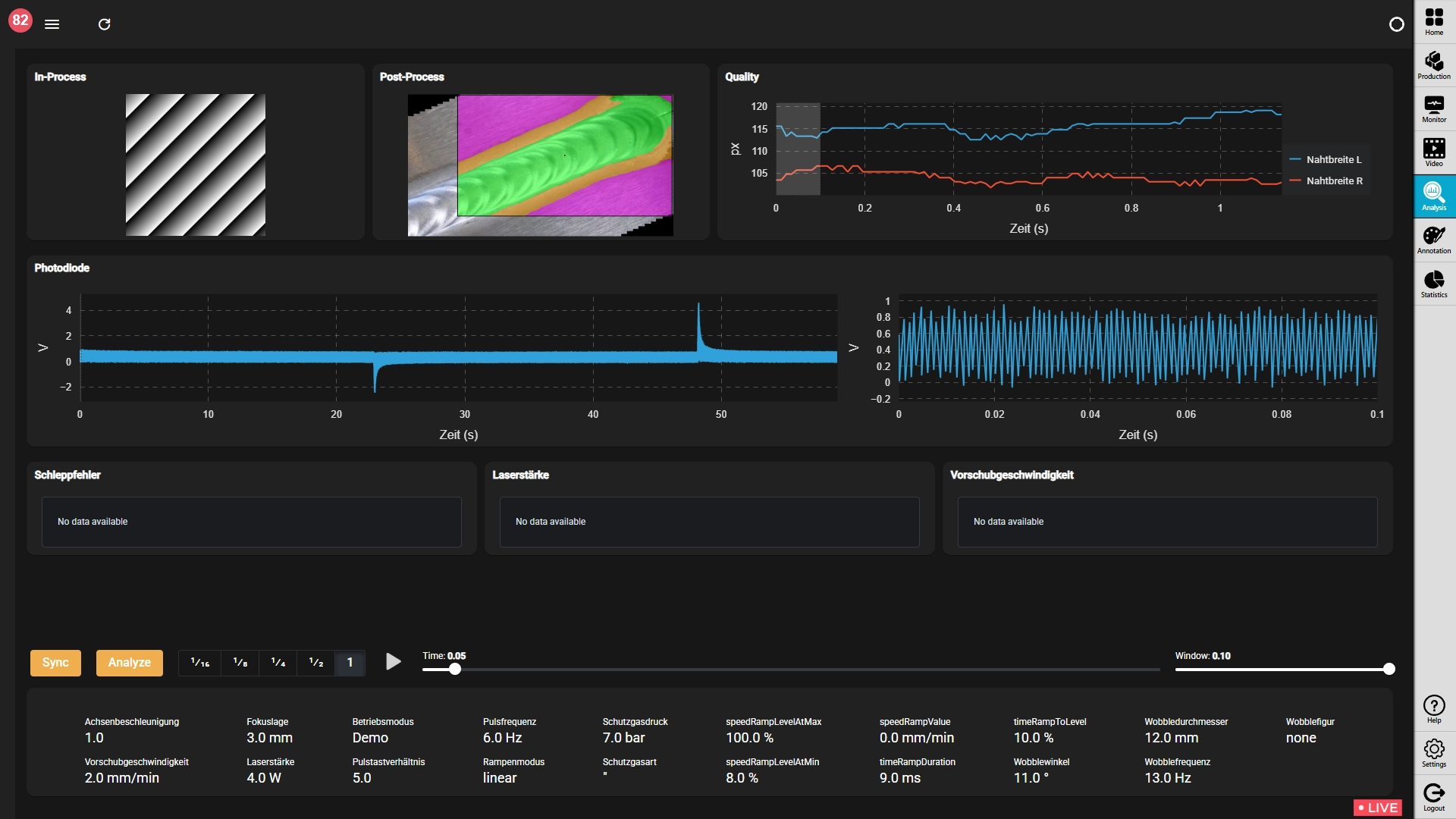

Software platform – modular, visual, process-oriented

The surface monitoring solution is based on a modular software platform specifically designed for complex manufacturing processes.

Core software modules

- Camera & video processing pipeline: live streaming, management and analysis of process videos; features such as zoom, bookmarks, calibration and measurements support analysis directly in the process context.

- Analysis & visualisation interfaces: process videos, AI results as well as sensor and machine data can be viewed synchronously. AI results are visualised directly in the video image.

- Dashboard & statistics modules: overview of data stocks, activities and quality metrics – per order and per workpiece.

This means that the process is not only monitored, but also represented in a transparent and traceable way.

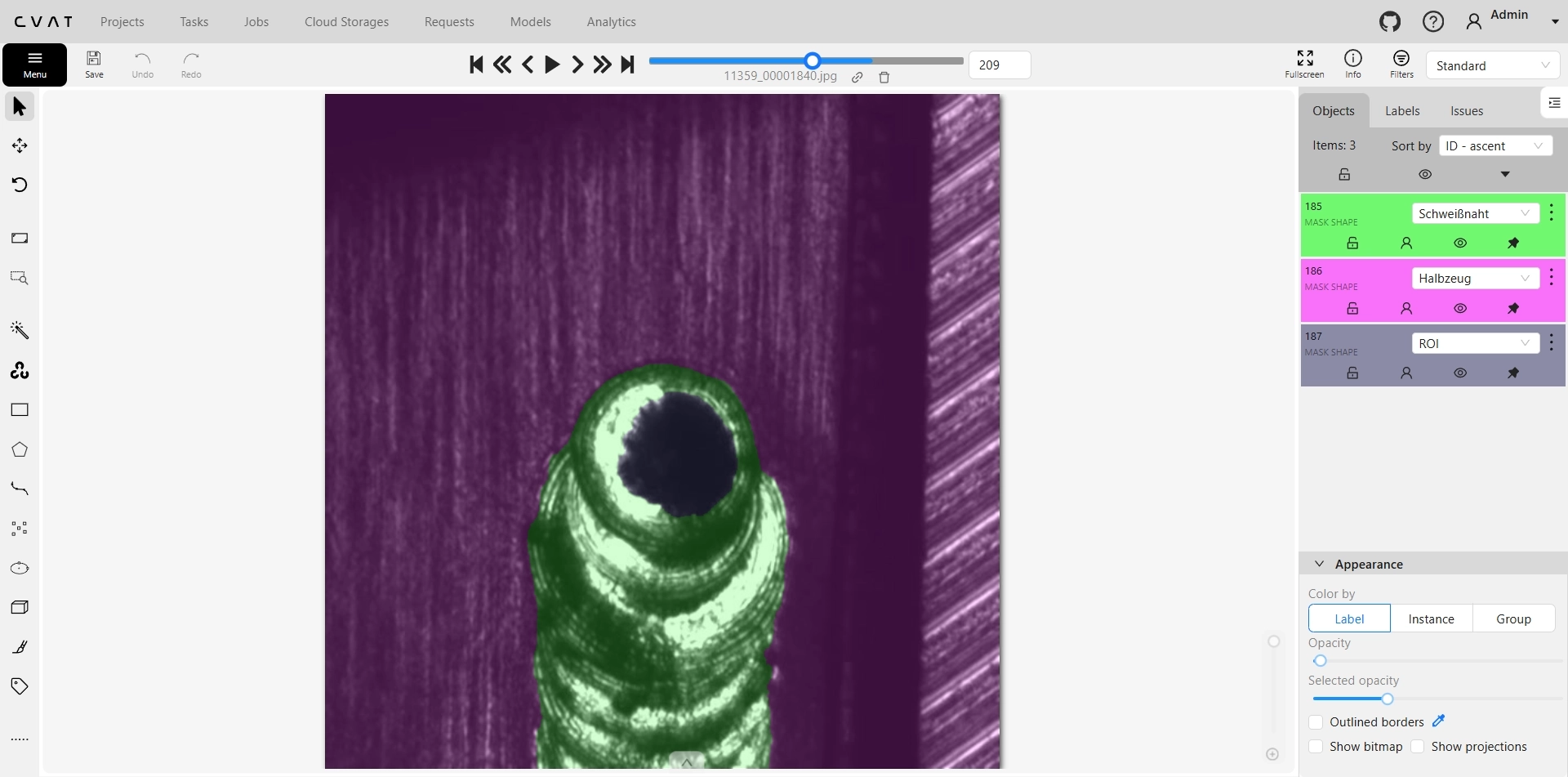

CVAT – structured annotation as the key to AI

For the creation of high-quality training data, clean annotation is crucial. To achieve this, the open-source tool CVAT (Computer Vision Annotation Tool) is seamlessly integrated into our system.

- videos are automatically split into individual frames

- annotations are carried out directly in a web-based workflow

- pre-segmentation speeds up the process

- recurring structures can be labelled efficiently

In this way, a scalable, industry-grade annotation process is created that significantly reduces the effort required for training data creation.

Segmentation – the basis for automated evaluation

A key step in quality assessment is image segmentation. Relevant surface regions are precisely separated from the background – the prerequisite for robust analyses. Segmentation enables:

- exact localisation of anomalies

- geometric measurements (e.g. seam width)

- consistent quality assessments

It forms the foundation for all further AI-based evaluations.

Artificial Intelligence – learning, evaluating, optimising

Based on segmented image and process data, AI and deep learning models are used to:

- automatically detect quality features

- reliably classify deviations

- evaluate processes based on the results

The models are designed so that they can also be trained with comparatively small data sets and continue to improve during live operation. In addition, workpiece properties (e.g. material, geometry) are incorporated into the evaluation together with system parameters – a key advantage over purely machine-centred solutions.

Sensor technology included – photodiode for precise signals

In addition to software and AI, we can also provide suitable sensor technology on request. A key component is our in-house developed photodiode solution, which captures high-frequency optical signals from the process.

- high temporal resolution

- focus on relevant spectral ranges

- robust, process-near integration

- reduced complexity compared to classic measurement systems

The result is a closed system of sensor technology, software and AI – perfectly aligned and tuned.

Added value for companies

- stable processes through continuous, data-driven optimisation

- verifiable quality at workpiece level

- higher productivity through reduced scrap and rework rates

- future-proofing through modular expandability and AI-based learning capability

Our surface monitoring solution is not an isolated inspection tool, but an integral part of modern, AI-supported process optimisation. It combines data acquisition, software, AI and sensor technology into a practical solution that makes complex manufacturing processes controllable, transparent and sustainably optimised.