weMonitor

weMonitor forms the basis for preventive maintenance (predictive maintenance) and effective production monitoring. The IIoT platform provides users with both an overview of all relevant machine and system data and extensive information for in-depth analyses. Based on innovative technologies, the platform is tailored and configured to your specific requirements.

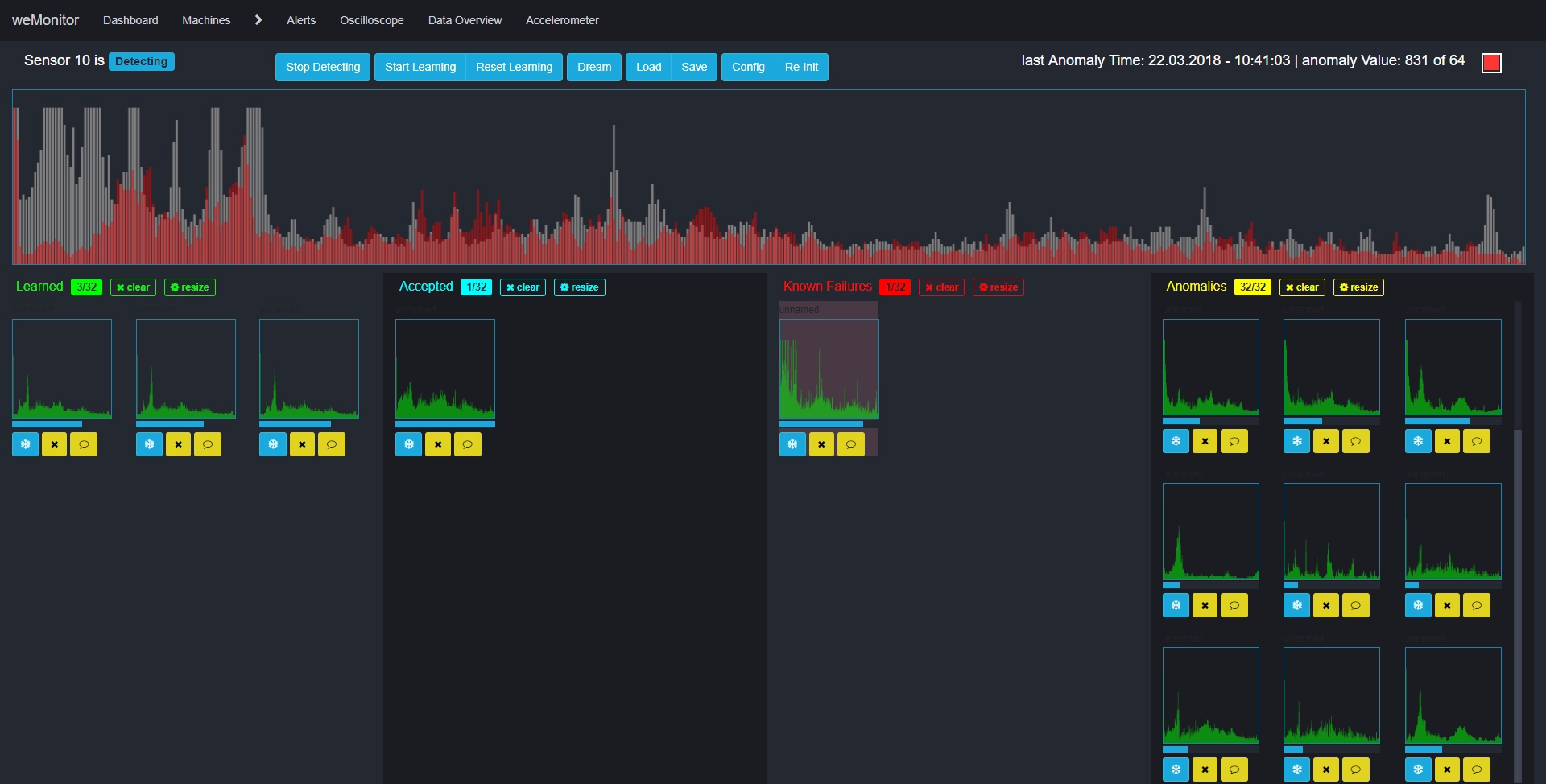

Forward-looking AI and machine learning methods are an integral part of weMonitor. They enable flexible, predictive maintenance by describing machines and systems with complex threshold values as an interconnected whole. In addition, these functions support the optimization of production process control. An automatic quality assessment system helps improve production processes with the goal of reducing costs and increasing capacity.

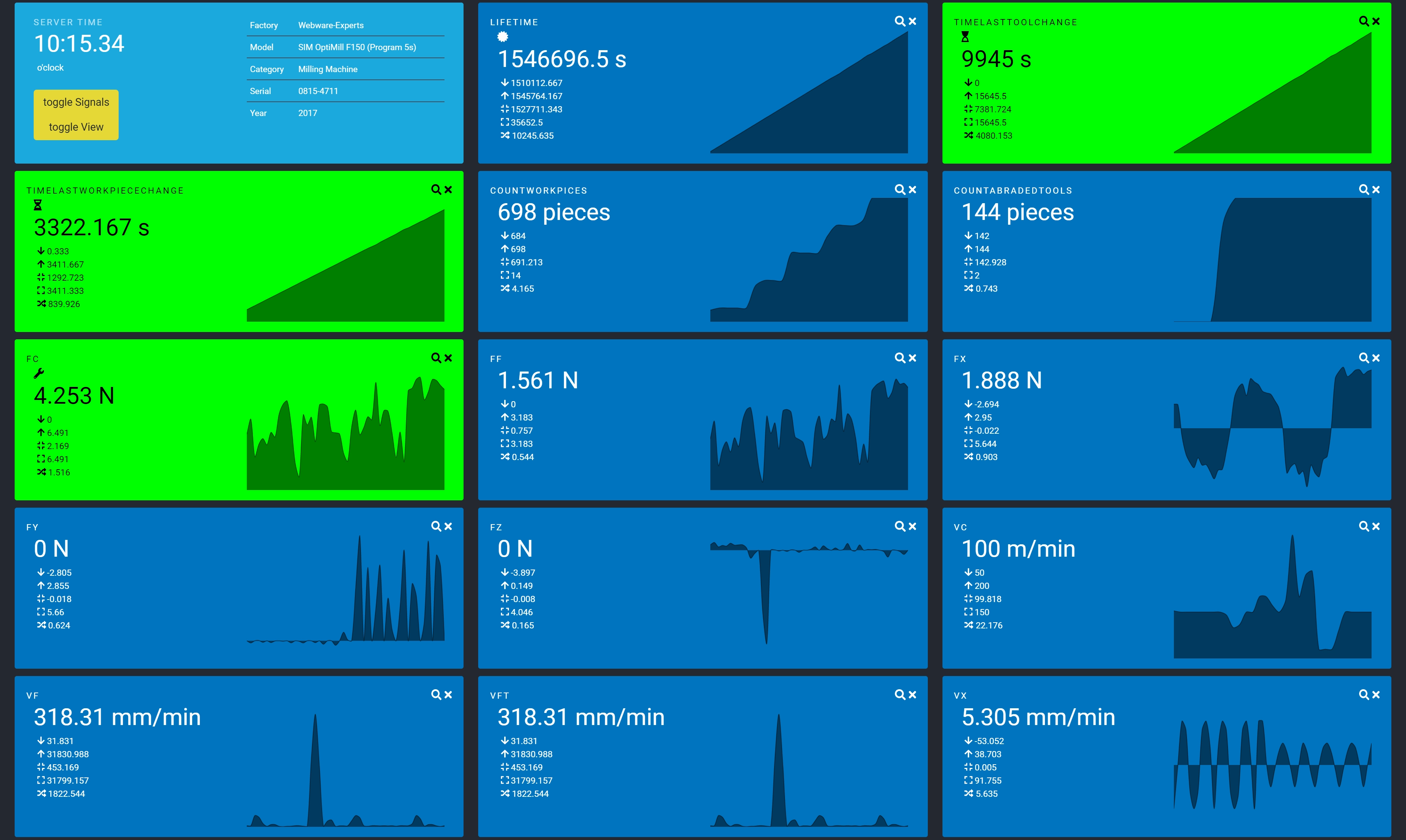

Realtime analytics

weMonitor’s real-time analytics offer various options for assessing the condition of a machine. A first overview is provided by the “Data Overview” section with different view options. On the one hand, the current machine values are displayed, supplemented by minimum and maximum values, averages, min/max differences, and standard deviations. On the other hand, an extended view allows the value trends to be displayed with further details. To carry out comprehensive real-time analysis, weMonitor provides the oscilloscope, which is used in particular for troubleshooting and subsequent signal analysis.

Lifecycle management

weMonitor enables users to perform efficient lifecycle management in the sense of quality assurance. The starting point is the central dashboard, which provides information indicating how prone different machine types are to faults. With the help of permanently stored alerts and the associated sensor data, manufacturers can identify the exact causes of frequent failures or issues. Based on these insights, improvements can be made to the affected machine systems. Another advantage is better maintenance planning for machine operators: they can see critical machine types at a glance and initiate countermeasures in good time.

Quality assurance

In terms of quality assurance, weMonitor issues early warnings to users when sensor thresholds are exceeded but no serious fault has yet occurred. Quality assurance also includes the predictive-maintenance functions, since early awareness of wear situations or problematic developments in sensor values enables preventive maintenance before quality losses occur during ongoing operation.

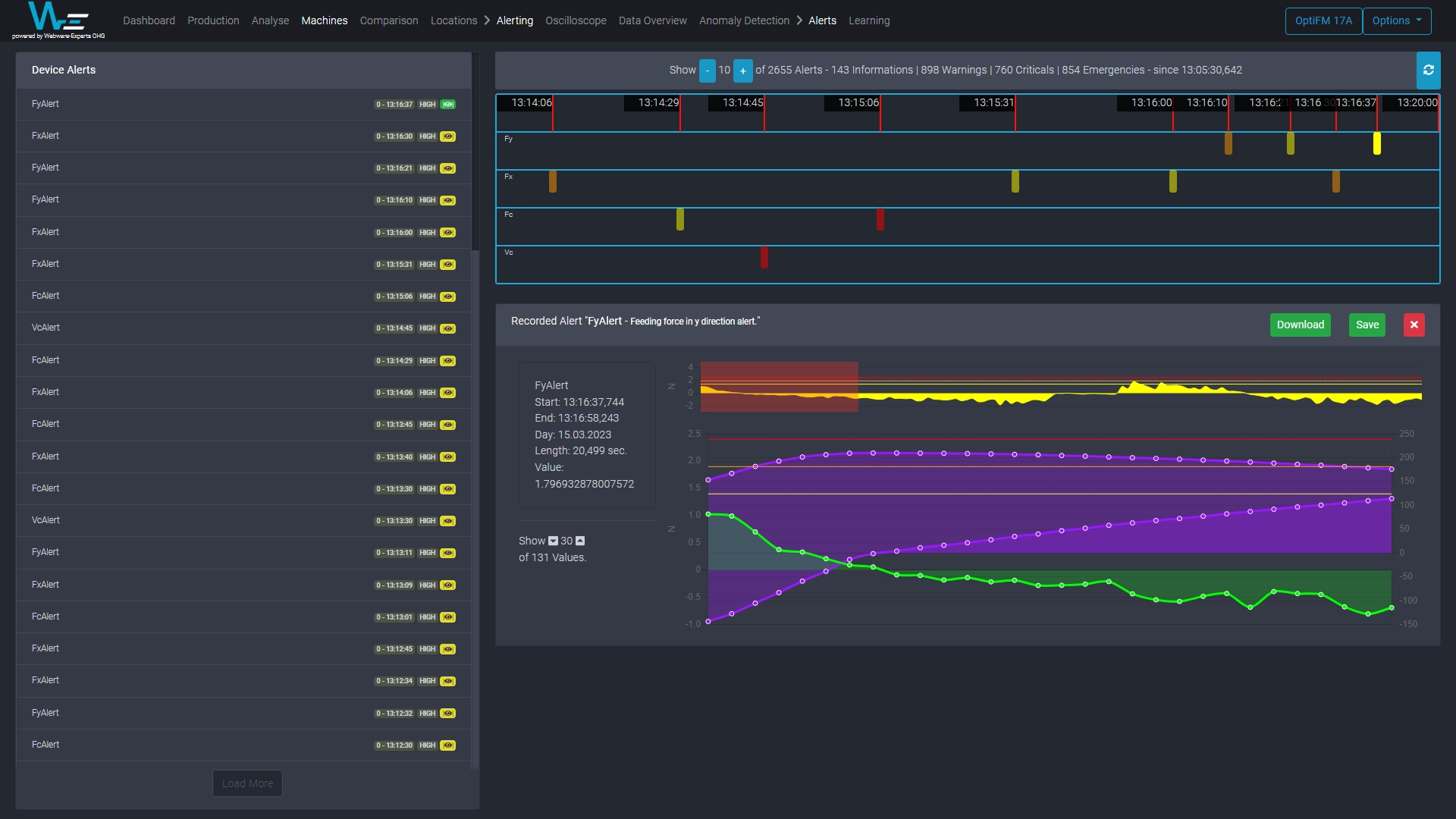

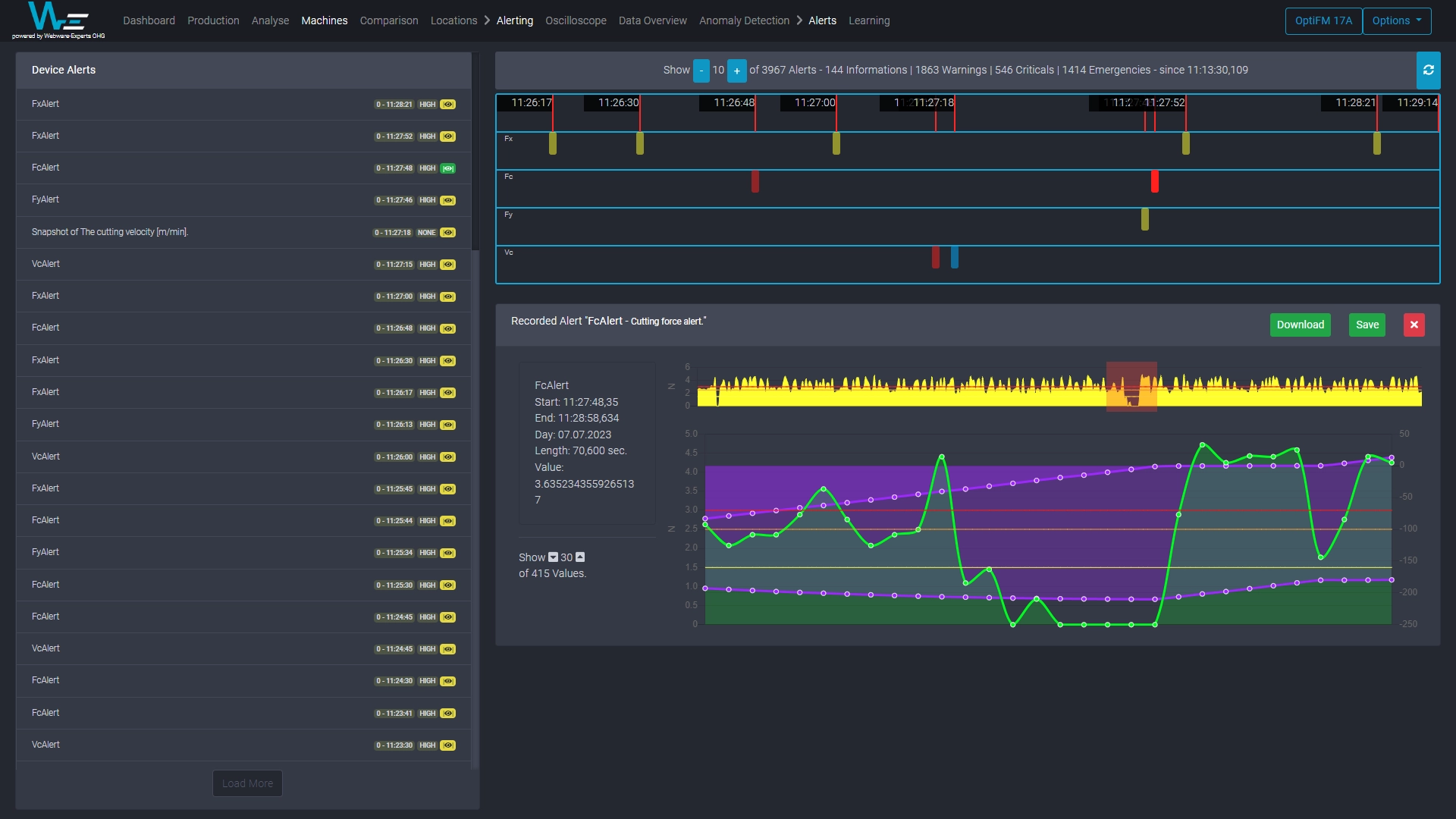

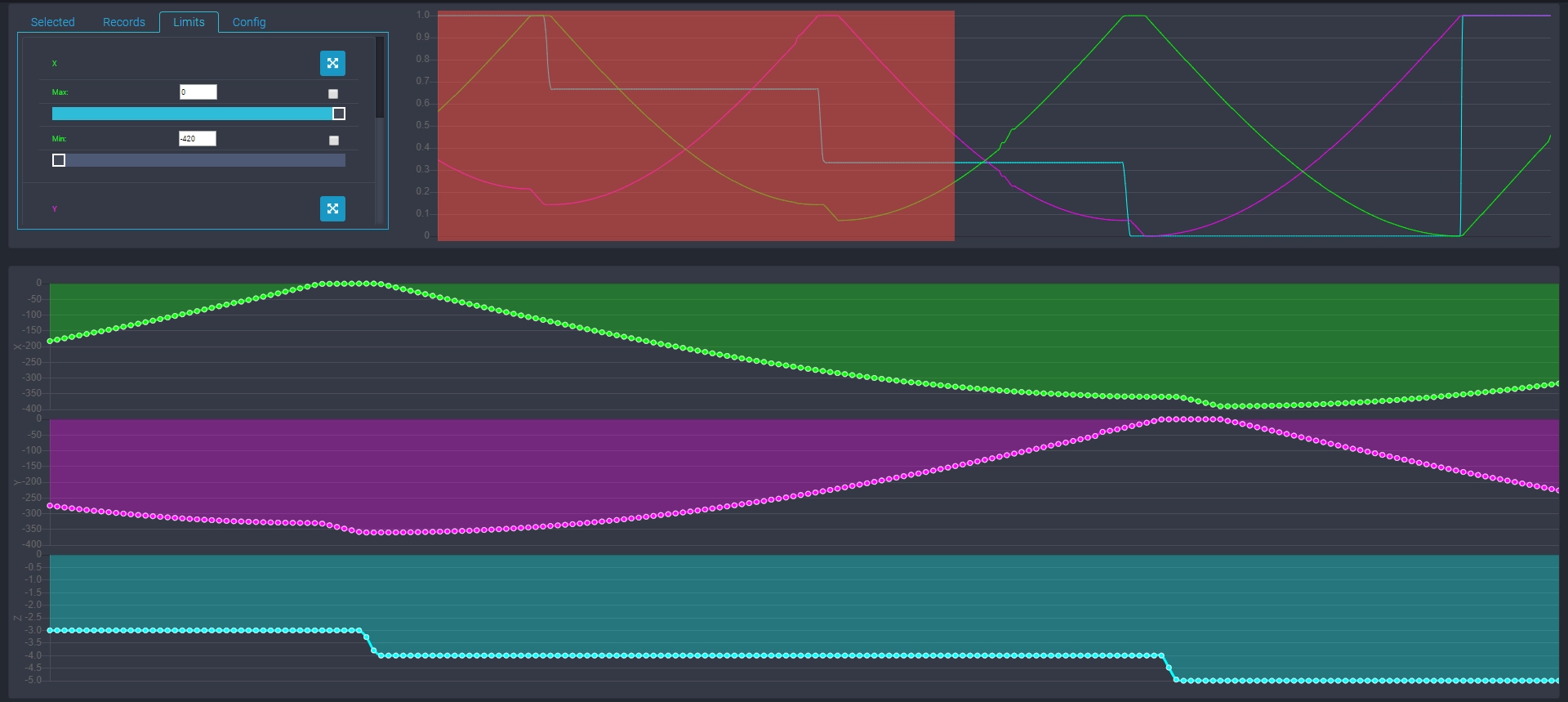

Monitoring / alerting

Alarm thresholds are defined for the respective machine sensors that must not be under- or exceeded. These can have the severity levels Warning, Critical, and Emergency. In addition, related signals can be selected: they are directly associated with the alert and are recorded and displayed when an alarm occurs. When an alert is generated, it appears both in an overview list and in a time-series diagram. Selecting an alert displays further detailed information.

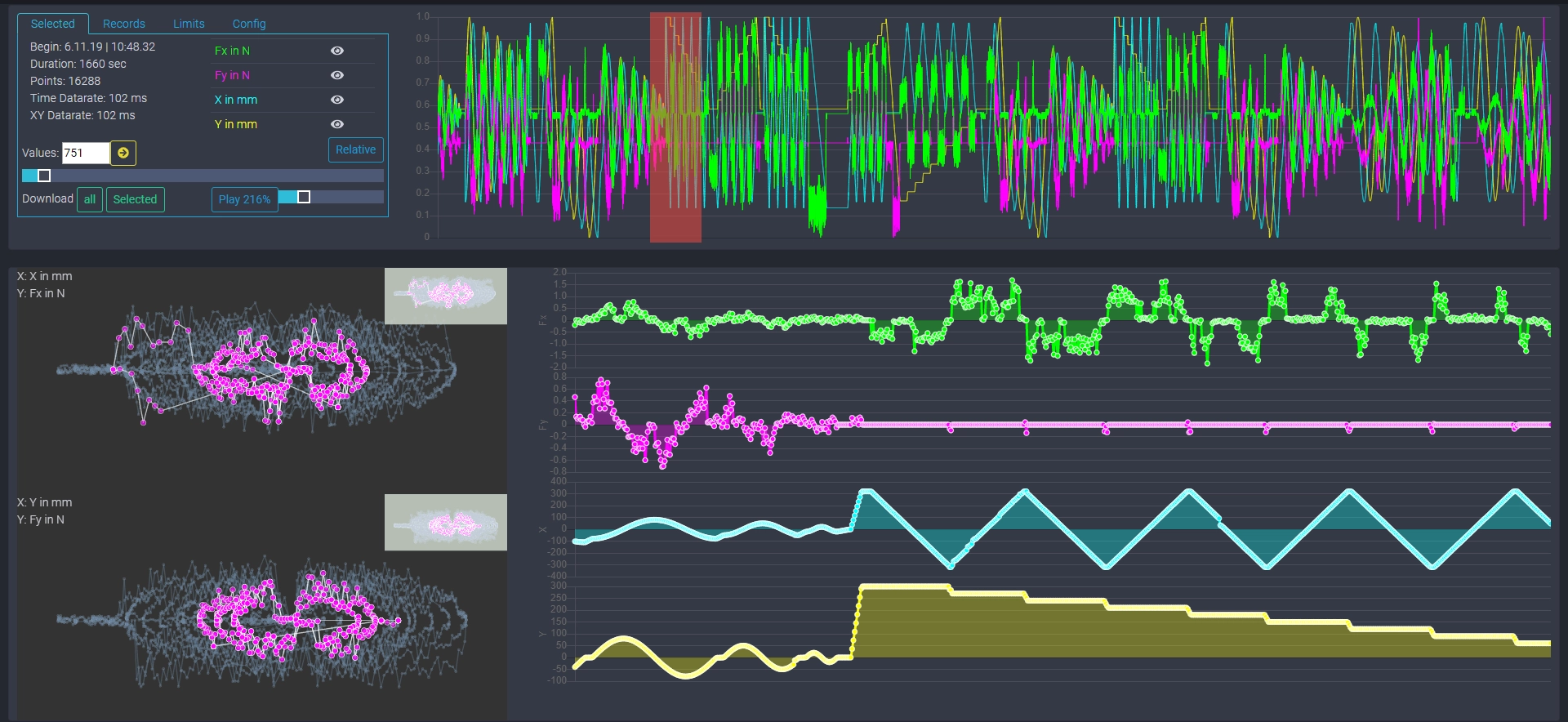

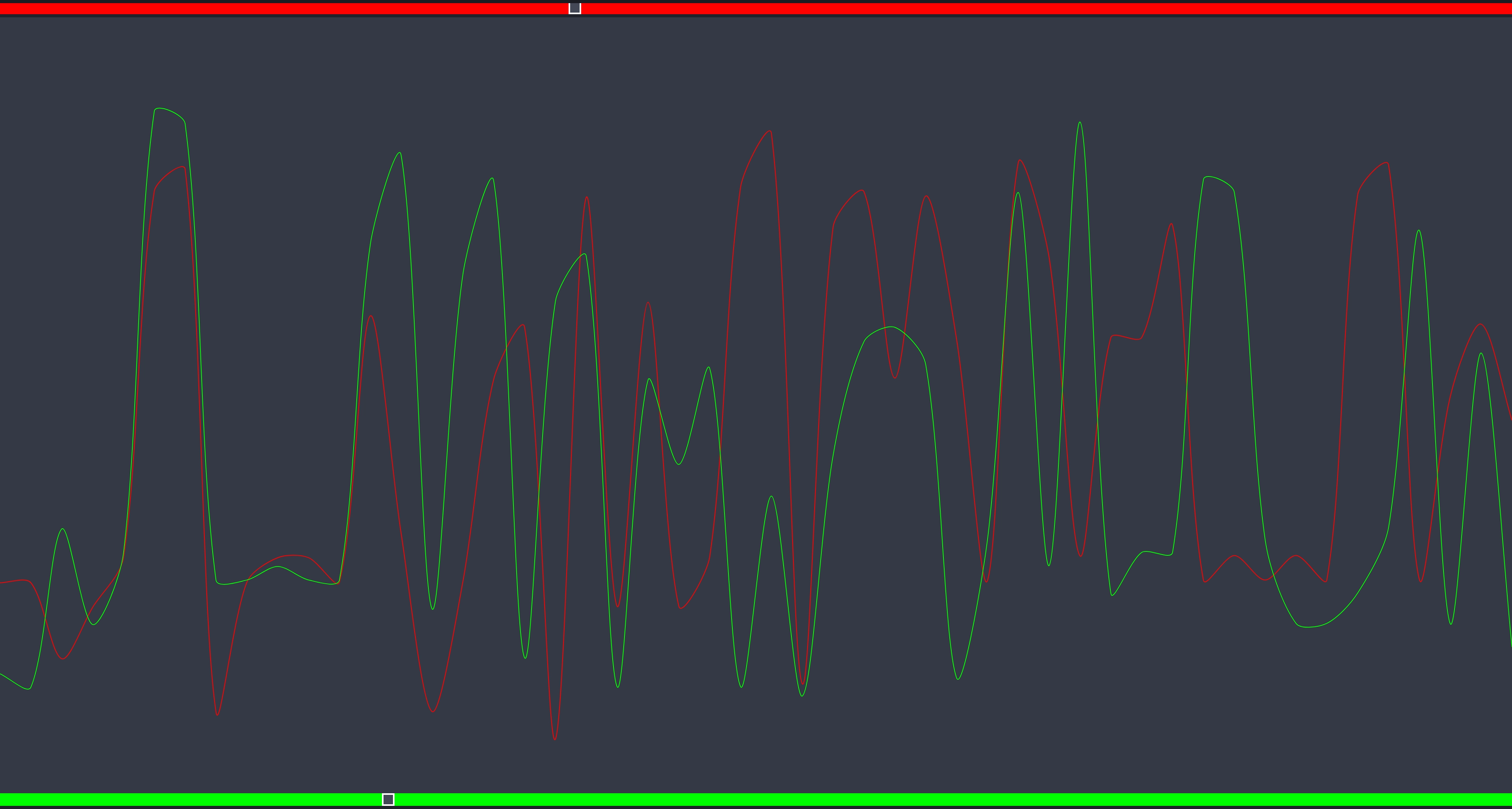

Troubleshooting

The different functions of weMonitor can be combined for troubleshooting. Stored sensor values can be compared with current values to identify deviations from optimal operation. In addition, sensor values can be analyzed in detail to check their plausibility and pinpoint the root causes of faults.

Signal analysis

Signal analysis is the core functionality of weMonitor. The recorded time series can be examined in detail in the integrated oscilloscope. It also supports users during the development and commissioning phases as well as in the ongoing operation of machines and systems.

Anomaly detection

weMonitor’s anomaly detection is a special form of AI-supported predictive maintenance, particularly suitable for complex situations. In this use case, a pair of sensors is trained and an AI system is configured based on certain predefined parameters. After the learning phase, this AI system monitors the corresponding sensors. Its capabilities go far beyond simple comparison of target and actual values. The underlying AI and machine-learning methods describe and analyze machines and systems with complex thresholds as an interconnected system. In this way, knowledge is generated autonomously based on self-collected experience. Predictive maintenance reaches a new level of performance, as the analysis of very large data volumes is automated and solution approaches for new and previously unknown problems can be derived.

Production monitoring

As a production monitoring system, weMonitor visualizes production processes based on collected machine and system data. This includes both cross-machine, process-oriented views and views that show key figures relevant to each individual machine or system (e.g. OEE). To enable detailed analyses, production monitoring data is linked with detailed sensor data that relates to the physical production processes. In addition, future image capture will enable automatic quality assessment. In this context, image and video information is recorded during production operations of machines and systems, enabling complex analyses of the corresponding processes.

Process control

The goal of optimizing process analysis is to detect problems and identify ways to improve the manufacturing processes of individual machines and systems. It is particularly suitable for complex processes with many different parameters defined by the user. Since systems in such scenarios cannot fully represent all possible variations of process control, standardized parameterization is often difficult. This is where weMonitor’s newly developed AI and machine-learning functions come into play. The automatic quality assessment system detects which process control patterns are beneficial and which are not. In this way, the production process improves itself, with the goal of reducing costs and increasing capacity.

Use-case videos

The following videos are currently available in German only.